Customer Support

T:+86 519 6822 0233

info@znshinesolar.com

info@znshinesolar.com

No.1, South Zhenxing Road, Zhixi Town Industry Concentration Zone, Jintan Zone, Changzhou, Jiangsu Province.

Views: 95 Author: Site Editor Publish Time: 2023-11-29 Origin: Site

Double glass photovoltaic modules stand out with remarkable advantages in power generation, embodying authenticity in their performance. The transparency and robust UV resistance of glass seamlessly align with the characteristics of double-sided cells, establishing a flawless synergy. When it comes to the module backsheet, the industry widely acknowledges the superiority of glass backsheets. In 2018, Joshua S. Stein from Sandia National Laboratories and Dirk C. Jordan from the National Renewable Energy Laboratory (NREL) conducted an in-depth review of double glass photovoltaic modules, delving into various pertinent issues.

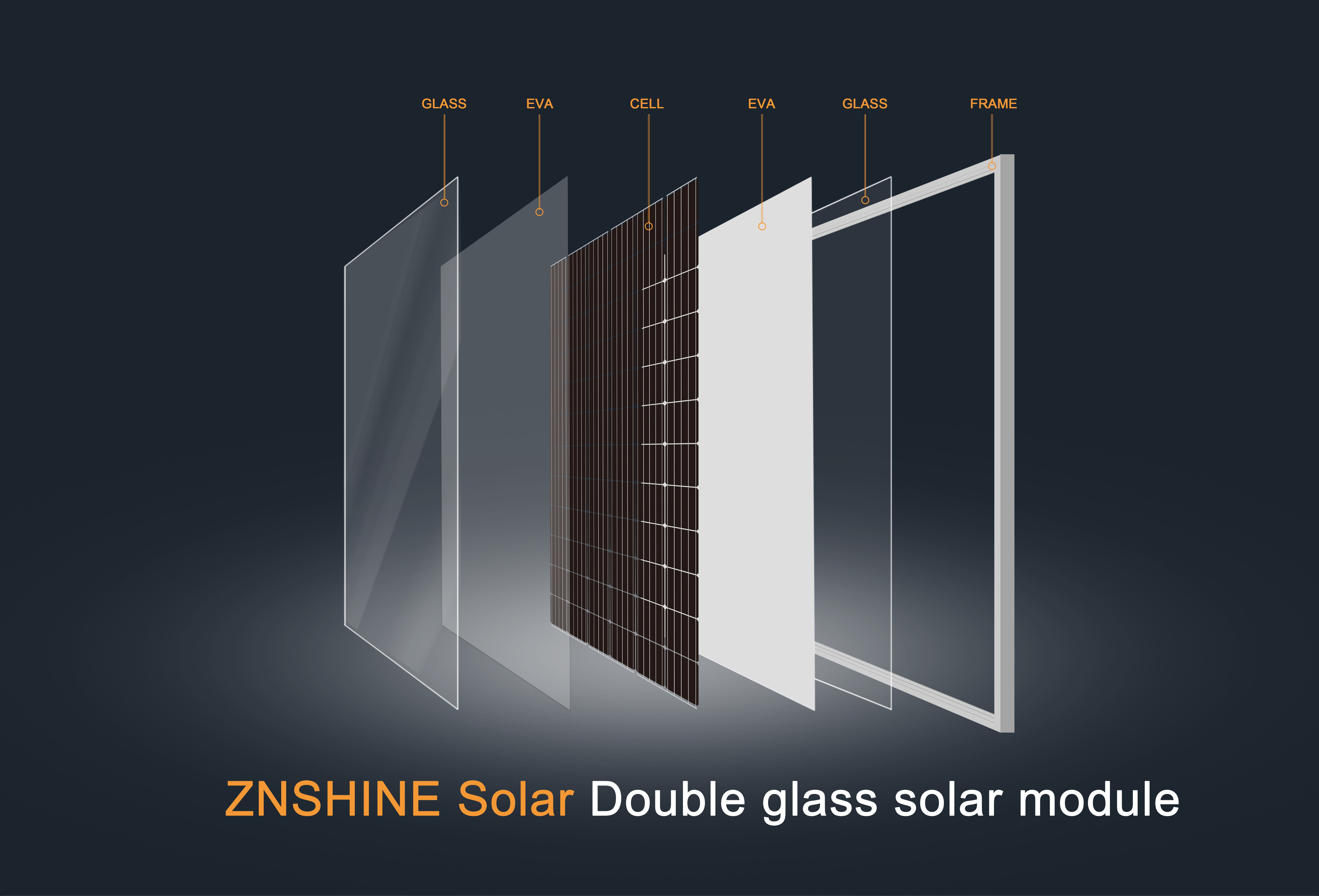

The conventional structure of solar panels typically encompasses photovoltaic glass, EVA film, solar cells, EVA film/white EVA film, and a photovoltaic backsheet. In contrast, double glass solar modules adopt an innovative design, featuring a double-layer glass in lieu of the traditional photovoltaic backsheet. This design, comprising front and rear double-layer glass and solar cells, not only significantly amplifies power generation performance but also mitigates the risk of local hidden cracks, thereby extending the module's lifespan.

Transparent Design Aesthetics

The innovative structure of double glass solar modules radiates excellence across various dimensions. First and foremost, their transparency confers a unique advantage in projects such as agricultural, fishing, and forestry complementarity. In the realm of photovoltaic glass greenhouses, these modules not only achieve photovoltaic power generation but also harmonize with the planting needs of crops inside the greenhouse. This not only enhances aesthetics but also introduces an element of visual appeal.

Physical Deformation Resistance, Chemical Reaction Resilience

Double glass modules, endowed with a symmetrical structure of two glass surfaces, exhibit heightened strength compared to traditional backsheets. The absence of a backsheet reduces the risk of local hidden cracks during construction and installation, while effectively curbing the deformation of solar cells, thereby diminishing the likelihood of microcracks during heavy snowfall. With glass as the primary component, double glass modules showcase remarkable resistance to chemical reactions, significantly bolstering the overall structure's corrosion resistance.

Improved and Stable Power Generation Efficiency

Double glass modules excel in dissipating heat during power generation, contributing to heightened power generation efficiency. Their dependable cell efficiency, anti-PID characteristics, enhanced low-light response, and adaptability to harsh outdoor environments empower them to achieve higher power output under various lighting conditions.

Extensive comparative test data from industry leaders unequivocally indicate that, after undergoing rigorous testing such as thermal cycling (TC), damp heat (DH), humidity-freeze (HF), and mechanical loads, the degradation level of double glass photovoltaic modules is noticeably lower than that of single glass modules employing polymer backsheets. Particularly noteworthy is their outstanding performance in resisting damp-heat aging: while single glass modules often struggle to pass DH3000 tests, double glass modules effortlessly navigate these tests, courtesy of glass's excellent water vapor barrier ability. Based on their stellar performance in stringent reliability tests, manufacturers of photovoltaic modules have extended the power warranty period of double glass modules to 30 years, accompanied by a commitment to a lower annual degradation rate.

Wide Range of Authentic Applications

In terms of application scenarios, double glass modules emerge as the go-to choice owing to their outstanding weather resistance and durability. They find suitability in photovoltaic power stations across various environmental conditions, including coastal areas, waterfronts, high-humidity regions, areas with severe acid rain and salt spray, as well as windy and sandy terrains like the Xinjiang Uygur Autonomous Region and the environs of the Sahara Desert in Africa.

In summary, double glass solar modules, with their authentic structure and exceptional performance, spearhead the development trajectory of the solar energy industry. By opting for glass over traditional backsheets in their design, these modules exhibit outstanding performance across diverse usage scenarios, presenting a more dependable solution for the promotion of clean energy. Choosing ZNSHINE's double glass modules encapsulates a host of advantageous features, culminating in a higher-performance solar energy solution.

The ZNSHINE Integrated PV, Energy Storage, and Charging System is built around the core concept of efficient and intelligent energy management, combining photovoltaic, storage, and charging functionalities. Tailored for residential, commercial, and industrial applications, this all-in-one clean energy solution leverages ZNSHINE's extensive expertise in the photovoltaic industry. Its flexible modular design caters to diverse application scenarios, significantly enhancing energy utilization efficiency while providing users with a low-carbon, convenient green energy experience.

In line with the global trend of energy structure adjustment and low-carbon development, ZNSHINE SOLAR introduces the ZNSHINE Integrated PV, Energy Storage & Charging System. Through technological innovation and efficient management, the off-grid mode of the system has become a new solution to address energy challenges in remote areas and regions with weak grid coverage. The ZNSHINE Integrated PV & Energy Storage System integrates photovoltaic power generation, energy storage, and intelligent control, offering high reliability and strong adaptability to provide users with sustainable clean energy solutions.

Industrial and commercial energy storage systems, as innovative power management solutions, are transforming the way businesses and enterprises utilize energy. By storing electricity during off-peak hours and discharging during peak times, these systems help reduce energy costs while serving as emergency power sources to ensure continuous supply during unexpected outages. This article delves into the energy storage segment of ZNSHINE’s Integrated PV&ES&CS System, showcasing its unique features and application advantages.

In recent years, the rapid development of solar photovoltaic (PV) technology has been accompanied by the continuous iteration of solar cell sizes. From the early 156mm era to today’s widespread use of larger 182mm and 210mm cells, each technological advancement has driven improvements in module power and optimization of system costs.

Graphene is hailed as the most revolutionary material of the 21st century, earning the title of "king of new materials" due to its exceptional properties. Composed of a single layer of carbon atoms arranged in a honeycomb lattice, graphene exhibits a range of remarkable physical characteristics. It is 100 times stronger than steel and has excellent electrical conductivity, with its carrier mobility at room temperature being approximately 10 times that of silicon. Additionally, graphene boasts outstanding thermal conductivity, with a thermal conductivity coefficient of up to 5300 W/mK, far surpassing most materials. Graphene is also nearly transparent, with an absorption rate of just 2.3% in the optical range. It retains excellent flexibility, allowing it to bend and deform while maintaining its structural integrity. These unique properties make graphene a material of enormous potential across various fields and are widely believed to herald a materials revolution.

When purchasing solar modules, performance and price are the two key factors to consider. The performance of a solar module depends not only on its photovoltaic conversion efficiency but also on the strength and durability of its structure. As a crucial support and protective component, the frame material has a direct impact on the overall performance of the module. Additionally, solar module frames, being high-value auxiliary materials, play a significant role in the module’s total cost structure. For instance, *the commonly used aluminum frame, with its strong mechanical properties, accounts for around 13% of the total module cost—surpassing other auxiliary materials like EVA, glass, backsheets, and solder ribbons—second only to the 55% cost share of the solar cells themselves.

Installing a solar photovoltaic (PV) system on a roof is a crucial process that requires ensuring the system efficiently captures solar energy while maintaining its safety and stability. This article will describe how to use the SRS (Solar Racking System) to install PV modules more securely and efficiently.

Una célula fotovoltaica es algo relativamente sencillo. Un material semiconductor, en el que se ha creado un diodo (se le ha dado polaridad), al que se le pone una capa azul antirreflejante y se conectan unos conductores eléctricos para extraer la electricidad. Digamos que la arquitectura de la célu